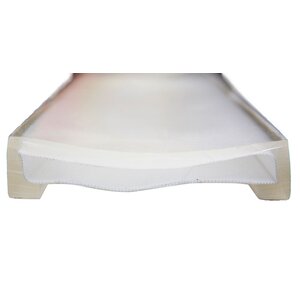

Applied directly to the lifting belts. The material and properties are the same as those of the Certex - Protect PU Protective Sheaths. In this way the highest levels of protection are afforded during the lifting process. The coating can be applied to all belt widths up to 300mm. Coatings can be single as well as double sided. In order to offer the required protection against cuts, coating thickness should not be less than 5mm. An advantage of the permanent nature of the coating is that the belt cannot be used unprotected. The material is the same PU Elastomer that is also used in the protective sleeves. There is the additional possibility of protecting the vulnerable lifting eye and hook areas. With loop belts a coating of the lifting eye areas is also possible, and hooks can be treated in various ways:

a) Lifting eye area coating. Here the lifting eye area is coated in a thin (ca 1-2mm) layer of PU as abrasion protection.

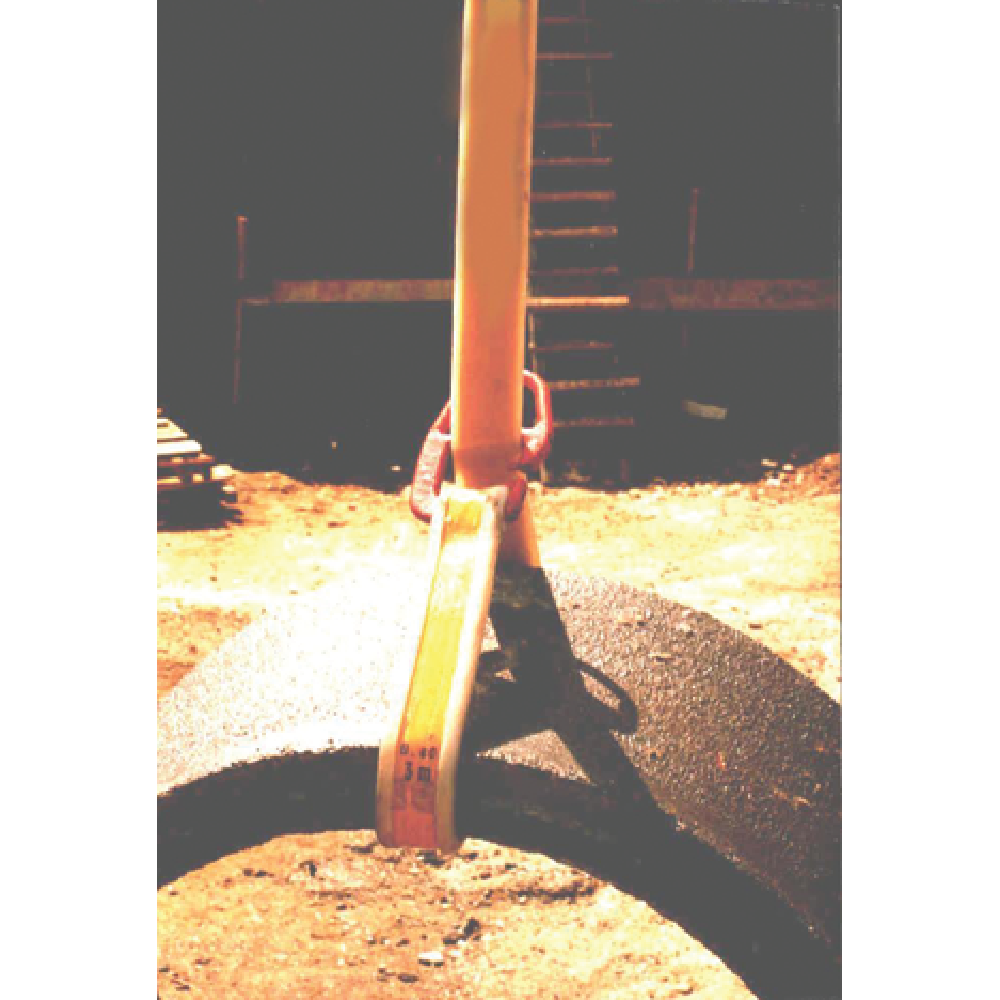

b) Loop Coating: the loop is protected by a 5-10 mm thick PU coating. (The loop remains fully flexible).

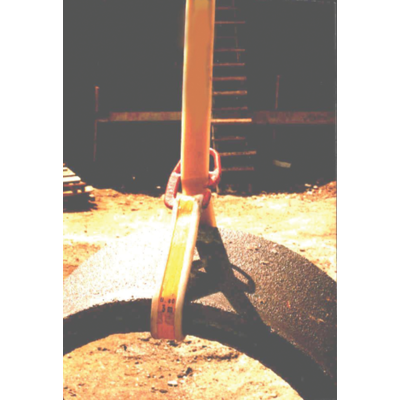

c) Stiff loop coating: similar to loop coating, but loop can no longer be moved (important if the belt is to be pushed under pressure).

The following should be noted: Due to the permanent nature of the coating, there is no movement of the belt within the coating, as is the case with the protective sheaths. As a result cargo can slip during the lashing operation as it can get snagged in the PU and move in an unplanned direction. This eventuality incurs high force levels and as a result particular care should be taken when loading cargo in this way.

Where webbing materials have been thickly impregnated the PU coating can become separated from the material. This could occur when the belt is stretched. The differing behaviour of PU and webbing when stretched can in rare cases lead to partial separation. Assistance can be given by white lifting belts that are attached but not impregnated. Needless to say a doubly impregnated belt offers excellent protection against moisture. Additionally PU by nature reduces slippage (e.g. smooth tube transport). It is possible to increase this slippage reduction for particular uses by either introducing rubber or wood shavings into the material, roughening of the material surface, or the use of foam as a material surface.

Additional elasticity 20 N/mm (DIN 53 515) Abrasion 60 mg (DIN 53 516)

Composition: PU Elastomer permanently bonded to webbing lifting belts or steel ropes.

- Material: Polyurethane Elastomer approx 80 Shore A, Elasticity 450% (DIN 53 504)

- Note: Whilst a certain protection against abrasion is achieved with thin coatings, resistance to cutting rises with coating thickness. A satisfactory resistance to cuts is achieved with a minimum