"The industry is changing, but safety remains key"

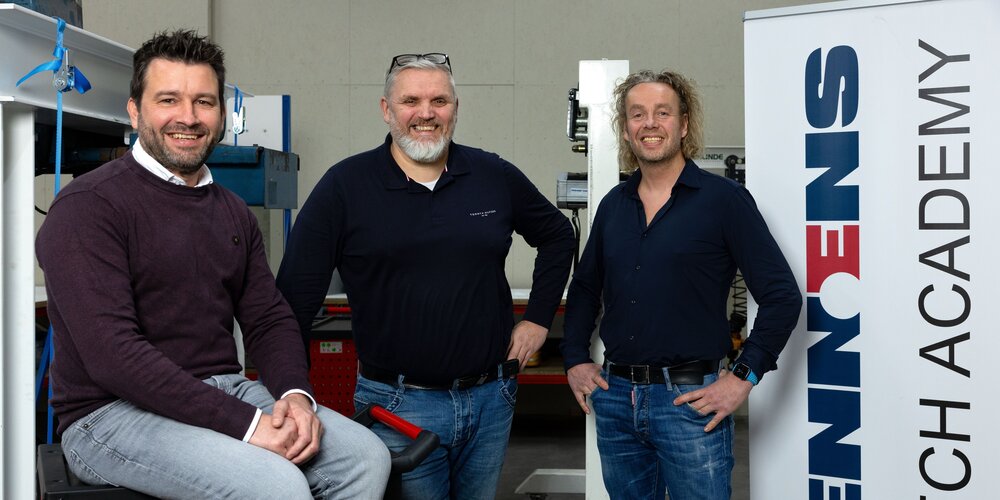

Operations manager Robert and service managers Job and Edwin on service and EKH

From the industrial port area in Rotterdam to rural Groningen and hilly South Limburg. Across the country, companies and organizations in various industries use the Mennens solutions. Mennens offers a total service package. Our EKH-certified inspectors come by periodically for an inspection and/or test. The goal: to ensure safety.

Job van Velzen and Edwin Sassen have both been working at Mennens since 2000. Initially as a service engineer for many years. Since 2017, they have been responsible for the service department. Job in Rotterdam, Edwin in Groningen. They ensure that all products are inspected and tested on time. Robert Jurgens does the same for the location in Hengelo.

| "Consider inspection and testing the general periodic inspection for your car."

Inspection and testing: the difference and the importance

At inspection and testing, the service technician checks that the equipment is still in working order. But what is the difference? Edwin explains: "Inspection is checking visually. Testing is inspection plus testing. Testing involves testing the hoisting equipment with the test load prescribed for that hoisting equipment to make sure the tested equipment holds the load it is supposed to hold. You don't check this regularly? Then accidents can happen."

"Moreover," Robert adds, "you are not complying with laws and regulations. And your entire business process can grind to a halt as a result. Consider it the MOT for your car. You want to be sure you can use the equipment safely."

About testing and inspection

Edwin: "We distinguish between 'above the hook': the installations (cranes, hoists, winches, etc.), and 'below the hook': the loose products (chains, hoisting belts, shackles, etc.). Everything below the hook is inspected once a year and tested according to prescription once a year or every four years. Everything above the hook is inspected and tested annually. We also inspect ladders and stairs, fall protection, cage ladders and steel wire ropes. We also do the NEN-3140 inspection of cord-connected equipment. So, it is very diverse!"

Increased awareness about safety

"Companies are becoming increasingly aware about safety," says Job. "They want to create a safe working environment for their employees." Robert: "The demands placed on our engineers are becoming stronger as a result. We want to have the right person with the right skills, certificates and training in the right place. Things have become stricter here in recent years - for the better. 'We either do it safely or we don’t do it at all' is a given. Although laws and regulations sometimes change, safety remains at all time."

A proactive attitude

"For the same reasons, we communicate proactively towards customers," says Job. "When a customer purchases a product from us, it automatically enters our database. A year later, we get a signal that this product needs to be inspected. We alert the customer and think along with them. It’s about partnership."

|"We think along with our customers proactively."

On site or in the workshop

The testing and inspection take place at the customer's location or in a Mennens workshop. Not everything can be inspected or repaired on location, and you don't just move a crane to any work location. "We are flexible since we offer both services," says Edwin. The advantages of testing and inspection in the workplace? Robert: "Conditions are optimal there, and we have everything at hand. We can also test materials with heavier workloads here than with a mobile tensile testing machine on site. The customer decides. But everything is customized, and we think along with them."

| "We stand for quality and safety."

EKH provides tools

Job: "Customers like the fact that we think along with them and provide advice. In the past, our service was sometimes seen as a butcher approving his own meat. Our years of reliable service and the arrival of the EKH changed that. This sector association for "Recognized Inspection Companies for Hoisting and Lifting Equipment" has been implementing current laws and regulations since 1993. For example, they issue certificates to our EKH-trained engineers who are regularly audited, go back for a day every 2.5 years and take an exam every five years." Mennens is also audited regularly as an EKH-certified company. Robert: "We are happy with that. After all, we stand for quality and safety and demonstrate that first hand."